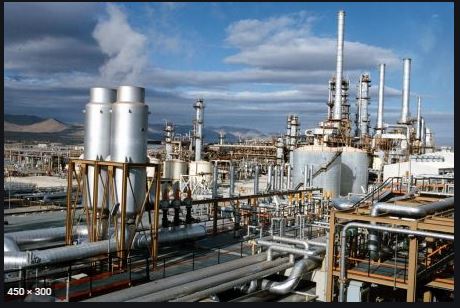

1989.01.09 / 1993.09.07-Dow Chemical Iberica, S.A. (filial de Dow Chemical Company). (es.dow.com). Maintenance and Deputy Manager and PPM Engineer. La Pobla de Mafumet (Tarragona). American multinational producer of hydrocarbon and derivatives, among others, ethylene and polyethylene. Sector: Petrochemical.

Description of the company

American multinational producer of hydrocarbon derivatives, among others, ethylene and polyethylene.

After taking over Union Carbide and merging with DuPont, Dow is the biggest petrochemical industry of the world. In Tarragona, Dow produces for sector like: packaging, industry, food, infrastructure, energy or automotive, among others. It works continuously, with programmed shutdowns of the plant every 4 years.

Reporting

In hierarchical dependence of the Maintenance Manager of the Tarragona North site. Functional reporting: the 5 area managers of the departments.

Main responsibility

It was double:

(1) Complete on the coordination of the Maintenance areas, planning and control, department costs, safety, Employee Satisfaction Surveys, etc., as well as the improvement of the operability of the general shutdowns.

(2) As Preventive and Predictive Maintenance Engineer, prevent and predict problems in the machinery and equipment, and also when they happened, before they were broken or collapsed.

Achievements

-

Due to my report about the Ethylene cracker of Dow-Terneuzen (Holland) and the comparison with ours, I was appointed Best Employee of the Year Award for Tarragona site, which I repeated due to the project of change of asbestos by graphite for gaskets and mechanical sealings, for static and rotating equipment, as well as the implementation of the new software, EMTS, made by the company itself in Midland (EEUU).

-

We introduced a cultural change in safety, through the american program Behaviour, based on the measurement of the human behaviour in front of safety. The sick and non-sick leave accidents decreased by 15%.

-

Reduction by 20% of the site rotating equipment incidents, by putting 10 vibration probes in the critical machines, directly connected to the production control room.